|

|

|||||||

1. Bottom-blowing Smelting Technology

Ø For Vietnam Sin Quyen Copper Complex Project, bottom-blowing smelting + PS converter process is adopted with copper concentrate treating capacity of 50,000 t/a. It was put into production in 2007.

Ø For the Modification and Expansion Project of Shandong Dongying Demonstration Project of Gold Collection in Matte with Oxygen Bottom-blowing Smelting Process, bottom-blowing smelting + PS converter process is adopted with the copper concentrate treating capacity of 250,000 t/a. It was put into production in 2008.

Ø For Comprehensive Refractory Gold Concentrate Recovery Modification Project of Shandong Humon Smelting Co., Ltd., bottom-blowing smelting + PS converter process is adopted with copper concentrate treating capacity of 300,000 t/a. It was put into production in 2010.

Ø For the Oxygen-enriched Bath Smelting Technology Modification Project of Baotou Huading Copper Development Co., Ltd., bottom-blowing smelting + PS converter process is adopted with copper concentrate treating capacity of 200,000 t/a. It was put into production in 2011.

Ø For the 500,000 t/a Polymetallic Mine Comprehensive Collection and Recovery Modification Project of Yuanqu Smelting Plant, bottom-blowing smelting + PS converter process is adopted with copper concentrate treating capacity of 500,000 t/a. It was put into production in 2014.

Ø For the Comprehensive Recovery of Metals from Smelting Slag and Waste for Henan Yuguang Gold and Lead Co., Ltd., bottom-blowing smelting + bottom-blowing converting process is adopted, with copper concentrate treating capacity of 500,000 t/a. It was put into production in 2013.

Ø For the Relocation and Upgrading Project of Henan Zhongyuan Gold Smelter Co., Ltd., bottom-blowing smelting + suspension converting process is adopted, and copper concentrate handling capacity is 1.5 million t/a. The project is under construction and expected to be put into production in 2015.

Ø For the 1 million t/a Polymetallic Mine Project of Dongying Lufang Metals Material Company Limited, bottom-blowing smelting + bottom-blowing converting process is adopted with copper concentrate treating capacity of 1 million tons. The project is under construction and expected to be put into production in 2015.

Ø For the Industrial Upgrading and Technical Improvement for Comprehensive Recovery of Gold and Copper, bottom-blowing smelting + PS converter process is adopted with copper concentrate treating capacity of 550,000 t/a. The project is under construction and expected to be put into production in 2016.

2. Flash Smelting Technology

Ø For the 400,000 t/a Copper Smelting Project in Guangxi Jinchuan Nonferrous Metals Raw Material Process Park, flash smelting + flash converting process is adopted with copper concentrate treating capacity of 1640000 t/a. It was put into production in 2013.

Ø For the Comprehensive Modification Project for Copper Smelting Energy Saving and Consumption Reduction of Jinchuan Group Co., Ltd., the synthetic furnace process is adopted with copper concentrate treating capacity of 200,000 t/a. It was put into production in 2005.

3. Top-blowing Smelting Technology

Ø For the 250,000t Copper Refining Project of Zhongtiaoshan Houma Smelting Plant, double top-blowing (Ausmelt) process is adopted with copper concentrate treating capacity of 300,000 t/a. It was put into production in 1999.

Ø For Energy-saving and Consumption Reduction Technology Improvement Project of Yunnan Copper Co., Ltd., top-blowing (ISA) + electric furnace + PS converter process is adopted, with copper concentrate treating capacity of 500,000 t/a. It was put into production in 2000.

Ø For the Smelting Technology Improvement of Tongling Jinchang Smelting Plant, top-smelting (Ausmelt) + electric furnace + PS converter process is adopted, with copper concentrate treating capacity of 300,000 t/a. It was put into production in 2003.

Ø For Hubei Daye Copper Smelting Energy-saving and Emission Reduction Project, top-blowing (Ausmelt) + electric furnace + PS converter process is adopted, with copper concentrate treating capacity of 1.5 million t/a. It was put into production in 2010.

Ø For Zambia Chambishi Crude Copper Smelting Plant Modification and Expansion Project, top-blowing (ISA) + electric furnace + PS converter process is adopted, with copper concentrate treating capacity of 500,000 t/a. It was put into production in 2010.

Ø For the 100,000 t/a Anode Copper Project of Sichuan Huili Kunpeng Copper Company Limited, top-blowing (ISA) + electric furnace + PS converter process is adopted, with copper concentrate treating capacity of 500,000 t/a. It was put into production in 2010.

Ø For the 100,000 t/a Copper Smelting Project of Yunnan Tin Company Limited, double top-blowing (Ausmelt) process is adopted, with copper concentrate treating capacity of 600,000 t/a. It was put into production in 2011.

4. Copper Electrolytic refining Technology

Ø For the 50,000 t/a Cathode Copper Project of Shandong Humon Smelting Co., Ltd., the technology with small sheet as starting sheet is used. It was put into production in 2010.

Ø For the 180,000 t/a Electrolytic Copper Project of Yunnan Copper Co., Ltd., the medium-size permanent cathode sheet process is used. It was put into production in 2010.

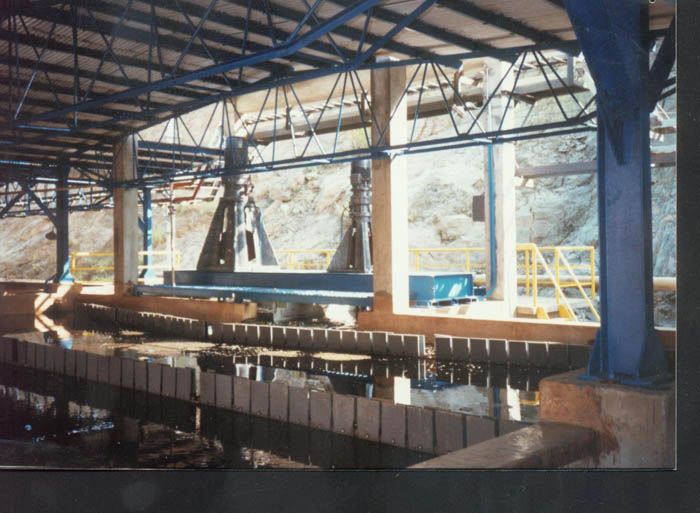

For the 300,000 t/a Electrolytic Copper Project of China Daye Non-Ferrous Metals Mining Limited, the large permanent cathode sheet process is used with imported equipment. It was put into production in 2012.

Daye 300,000 t/a permanent cathode electrolysis tank house

Ø For the 100,000 t/a Electrolytic Copper Project of Henan Yuguang Gold and Lead Co., Ltd., the large permanent cathode sheet process with made-in-China equipment are used. It was put into production in 2013.

Ø For the 400,000 t/a Electrolytic Copper Project of Zhongyuan Gold Smelter under China National Gold Group Corporation, large permanent cathode sheet process is used with the imported equipment. It is expected to be put into production in 2015.

5. Copper Hydrometallurgical Technology

Copper hydrometallurgical technologies include heap leaching, concentrate roasting – leaching and agitation leaching. Copper cathode is obtained from leachate by extraction and electrowinning.

5.1 Heap leaching

Heap leaching: heap leaching includes waste rock heap leaching and ore heap leaching. The copper-bearing waste rocks or ores are piled up and laid with solution pipes on the heap in order to spray solution to have copper leached. The resulting copper-enriched solution goes through extraction and electrowinning to obtain cathode copper. Representative projects include Dexing Copper Mine Project of Jiangxi Copper Corporation (JCC) and the project of Duobaoshan Copper Industry Co., Ltd.

Ø For Dexing Copper Mine Project of Jiangxi Copper Corporation (JCC), heap leaching is applied for copper-bearing waste rocks. It is a project using "copper-bearing waste rock heap leaching - extraction-electrowinning plants" process. It is the first plant in China to adopt bio-leaching process for primary sulfide waste rock, with an annual output of 2,000t/a Grade A cathode copper. In the project, the large-sized extractor (with design solution flow rate at 320m3/h) and mixing chamber of extractor in double stirring mode are used. The super large permanent cathode sheet technology and other technologies have been awarded with the second prize of Science and Technology Progress Prize by State Non-Ferrous Metal Industry Bureau. The project was completed and put into production in 1997.

In Duobaoshan Copper Industry Co., Ltd., oxidized ore heap leaching, extraction and electrowinning process are used with annual output of 3000 t/a cathode copper. It was put into production in 2009.

5.2 Concentrate roasting - leaching

Concentrate roasting - leaching: copper concentrate is roasted firstly to get copper sulfate or copper oxide which goes through water leaching or acid leaching to obtain copper-bearing solution. Then after extraction and electrowinning, cathode copper is obtained. Representative projects include Shandong Humon Smelting Co., Ltd. and Cobalt & Copper Smelter of Hainan Steel & Iron Company.

Ø In Shandong Humon Smelting Co., Ltd., the process of sulfur concentrate roasting - extraction - electrowinning is applied to recover copper from precious metals, achieving a production of 1000t/a cathode copper. It was put into production in 2002.

Ø In Cobalt & Copper Smelter of Hainan Steel & Iron Company, a process of cobalt and sulfide concentrates roasting - extraction - electrowinning is applied to recover copper, achieving a production of 1000t/a cathode copper. It was put into production in 2003.

5.3 Agitation leaching

Agitation Leaching: copper-bearing ores and acid are leached at a certain proportion in agitation tank with the controlled temperature, time and acidity. The copper-bearing slurry is obtained for solid-liquid separation to get copper-bearing solution, which is further treated by extraction and electrowinning to obtain copper cathode finally. Representative project includes Tibet Yulong Project.

Ø The Tibet Yulong 15,000 t/a Electrolytic Copper Agitation Leaching Project is located at an altitude of 4800 meters, which is a copper smelting project with the highest elevation in China, and a process of copper oxide ore crushing - grinding - agitation leaching - extraction - electrowinning is used in the project. It was put into production in 2013.

5.4 Extraction

The copper extraction process mostly includes sections of agitation leaching, thickening, copper extraction, CCD scrubbing and cobalt precipitation and recovery. The copper-bearing solution after leaching will go through copper extraction and purification and then electrowinning to obtain cathode copper. Copper extractors designed by ENFI for projects of Shanxi Yangquan, CDM and Mabende are made of pure stainless steel, which were put into operation successfully.

Shanxi Yangquan project with a design capacity of 1000t/a, is the first copper and cobalt processing enterprise in China. The copper extractor designed by ENFI for the project created precedence of directly recovering copper from copper and cobalt ores by extraction.

CDM copper extractor project with a design capacity of 10,000 t/a, is the first one using extractor made of material 316L with mixing chamber diameter of 2400mm, and clarification chamber specification of 11,000X6,500mm. The project was put into production in 2013 and has good performance up to now. The current capacity has reached 15,000 t/a.

Mabende copper extractor project has a design capacity of 30,000 t/a. The extractor of double stirring mode is made of pure stainless steel with a diameter of 3,000mm, clarification chamber specification of 24,000X16,500mm, which is the largest copper extractor made of 316L and designed by ENFI.